Hastelloy anticorrosive claw pump

Hastelloy anticorrosive claw pump Characteristic

1) It is specially developed for the highly corrosive working condition of pharmaceutical and chemical industry. The flow passage surface of dry claw pump is made of Hastelloy composite material, which can adapt to the severe working condition, especially resistant to strong acid and alkali corrosion such as hydrochloric acid and sulfuric acid.

2) The water removal system can be arranged in front of the Hastelloy corrosion-resistant claw pump to reduce the moisture content in the material, thus greatly reducing the corrosiveness of acid and alkali in the material to the dry pump.

3) The pump temperature regulating system can be configured to accurately control the pump body temperature according to the actual working conditions, reduce the condensation of acid materials in the pump cavity, and reduce the corrosion of acid solution to the pump.

4) It can be equipped with an automatic cleaning system, which can automatically clean the pump cavity and dry it with nitrogen before or after the vacuum pump works, greatly extending the continuous working time of the vacuum pump, and ensuring the normal start-up of the vacuum pump after the shutdown.

5) The immersion circulation cleaning system can be configured to thoroughly clean the pump cavity after the vacuum pump is shut down, so as to prevent the corrosion of the pump by the remaining corrosive materials in the pump cavity during the shut down period of the vacuum pump, thus greatly extending the service life of the pump.

Hastelloy anticorrosive claw pump Application

It is specially designed for the development of highly corrosive working conditions in the field of chemical industry and medicine. It is suitable for the development of highly corrosive processes including chloride ion, fluorine ion, sulfate ion and nitrate ion in materials, such as molecular distillation, drying, degassing, evaporation, distillation, filtration, organic solvent recovery, biotechnology, etc.

1) polymerization

2) Organic solvent recovery

3) Dyes, coatings, adhesives

4) Plastics and resins

5) Oil chemistry

6) flavors and fragrances

7) Vitamins, sugar

8) small test

9) food

10) Metal treatment

Technical parameter — specifications

| Model | Outline size/mm | Weight (excluding motor)/kg | Extreme vacuum/Pa | speed/rpm | Pumping rate/L/s | Full load power/Kw | input voltage/V | Noise/Db | Cooling water flow/L/h | Cooling water inlet temperature/℃ | Cooling water inlet pressure/Mpa | Intake port/mm | Exhaust port/mm | ||

| 长 | 宽 | 高 | |||||||||||||

| YY-30PHC | 563 | 515 | 1069 | 213 | 3 | 2900 | 30 | 4 | 380 | 75 | 350 | ≤35 | 0.2-0.4 | DN40 | DN32 |

| YY-70PHC | 753 | 628 | 1373 | 550 | 3 | 2900 | 70 | 7.5 | 380 | 78 | 800 | ≤35 | 0.2-0.4 | DN50 | DN40 |

| YY-110PHC | 753 | 628 | 1590 | 630 | 3 | 2900 | 110 | 11 | 380 | 78 | 1000 | ≤35 | 0.2-0.4 | DN50 | DN40 |

| YY-150PHC | 807 | 756 | 1678 | 730 | 3 | 2900 | 150 | 15 | 380 | 78 | 1000 | ≤35 | 0.2-0.4 | DN65 | DN50 |

| YY-200PHC | 927 | 875 | 1763 | 962 | 200 | 1400 | 200 | 22 | 380 | 80 | 1200 | ≤35 | 0.2-0.4 | DN80 | DN65 |

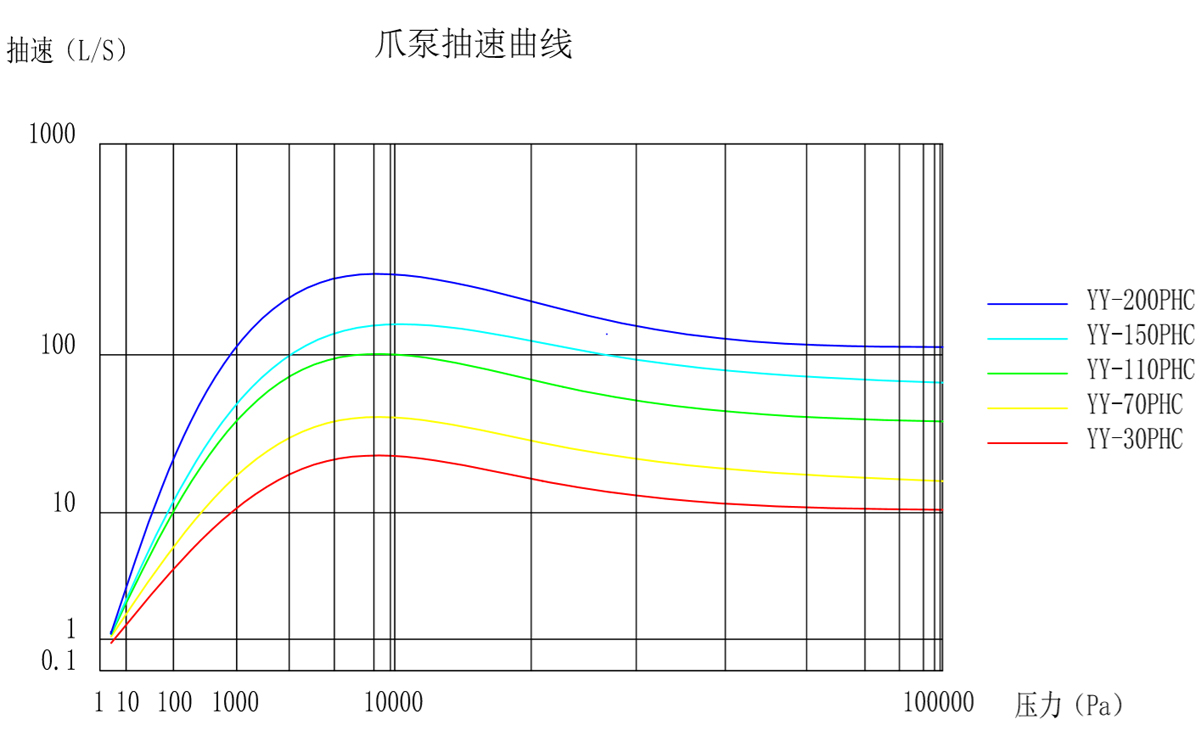

Technical parameter — performance curve